Dangerous Goods Packaging: The Ultimate 2025 Guide

Whether you're in the chemical, pharmaceutical, manufacturing, or automotive industry, shipping dangerous goods is a daily reality. It's a critical operation that involves the safety of people, environmental protection, and your company's reputation. But faced with dense regulations (ADR, IATA, IMDG) and high risks, choosing the right packaging can quickly become a real headache.

This guide is not just a simple product catalog. It's a simple two-step method, designed to allow any logistics or compliance professional to select the perfectly adapted and compliant packaging for their needs, with complete confidence.

A wrong choice can have immediate consequences: a shipment blocked at customs, fines for non-compliance, and in the worst case, a safety incident. How can you ensure making the right choice every time?

Before Choosing Packaging: The Principle of Shipper Responsibility

Before even looking at packaging, it's fundamental to understand a key principle that underlies all dangerous goods transport regulations: shipper responsibility.

What does this principle say?

According to international regulations (ADR for road, IATA for air, IMDG for maritime), it's always the company that initiates the shipment that is legally responsible for the shipment's compliance. This responsibility cannot be delegated to the carrier. It covers:

- Correct classification of the goods.

- Choice of appropriate and certified packaging.

- Correct marking and labeling of the package.

- Provision of accurate and complete transport documentation.

In this context, UN homologated packaging is not just a box. It's tangible proof that you, as the shipper, have taken the necessary measures to ensure safety. It's your compliance insurance, the barrier that protects your responsibility.

Simple 2-Step Method

Consult your Safety Data Sheet (SDS), section 14 to obtain: UN Number, Packing Group, Packing Instruction

Choose the packaging family according to your product's physical characteristics and your logistical constraints

Step 1: Correctly Identify Your Dangerous Good

The golden rule is simple: the choice of packaging depends 100% on the product you're transporting. All the information you need is found in a document you must absolutely master: your product's Safety Data Sheet (SDS), and more particularly its section 14, "Transport information".

Here are the three key pieces of information you must find there.

Find the UN Number

The UN number is the universal "identity card" of your dangerous good. It's a four-digit code that allows unambiguous identification anywhere in the world. For example:

UN 1263 for Paint.

UN 1993 for Flammable liquid, n.o.s. (not otherwise specified)

UN 3480 for Lithium-ion batteries.

This number is the starting point of your entire approach.

Determine the Packing Group (PG)

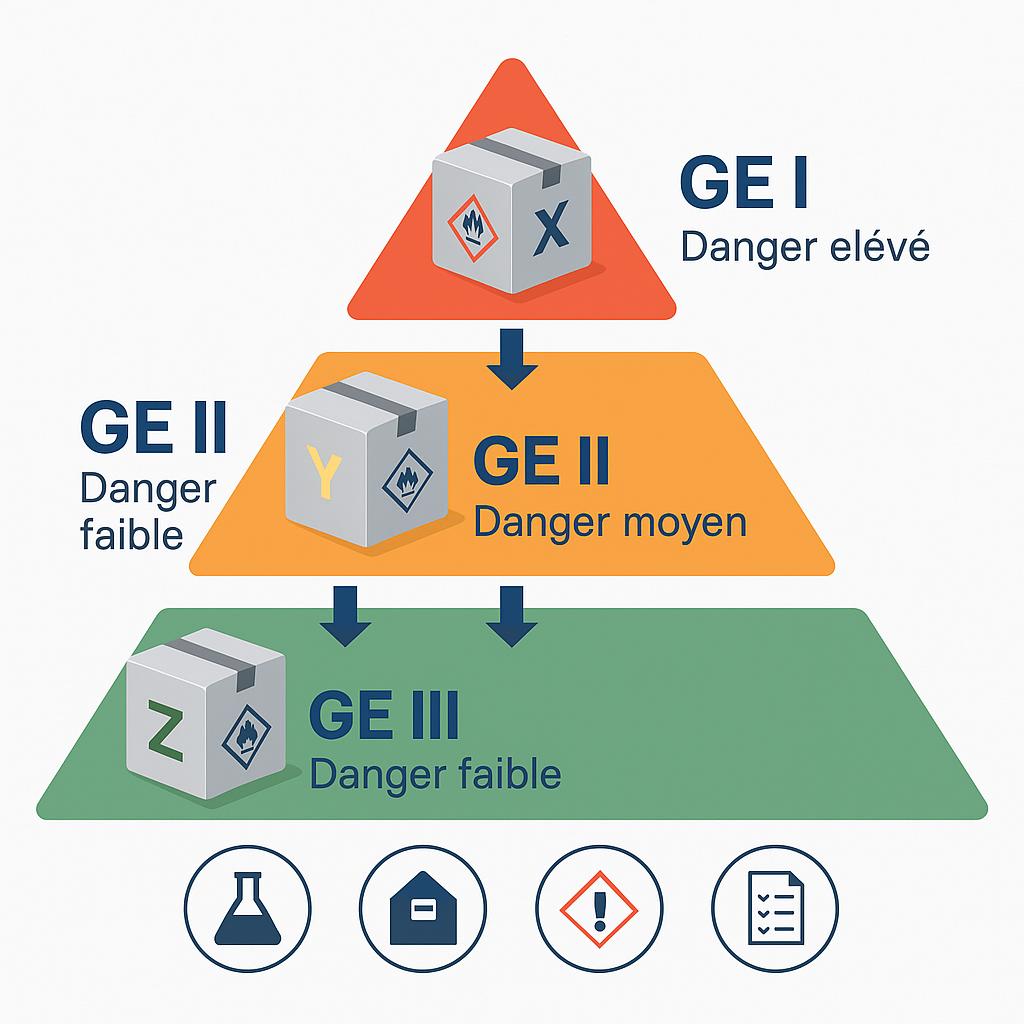

The Packing Group (PG) indicates your product's danger level. It's crucial because it determines the performance level required for your packaging. There are three levels:

- PG I: High danger. Requires the most resistant packaging, marked with the letter "X".

- PG II: Medium danger. Requires intermediate resistance packaging, marked with the letter "Y".

- PG III: Low danger. Requires standard resistance packaging, marked with the letter "Z".

An "X" marked packaging can transport products from groups I, II and III. A "Y" packaging can transport products from groups II and III. A "Z" packaging can only transport group III products.

Consult the Packing Instruction (PI)

The Packing Instruction (PI) is the "recipe" provided by regulations. It's a code (e.g., P001, P903 in ADR) that tells you precisely how to pack your product: what type of packaging is authorized, what are the maximum quantities per inner receptacle and per package, and if there are specific cushioning requirements.

Step 2: Select Homologated Packaging Adapted to Your Product

Once your product is identified, the choice of packaging depends on its physical characteristics and logistical constraints.

For Lithium Batteries (Class 9)

Transport of lithium batteries (UN 3480, UN 3481) is one of the most common industry challenges. It requires robust packaging, certified for Class 9, with quality internal cushioning to prevent short-circuits.

Discover our solutions dedicated to lithium battery transportFor Biological and Pharmaceutical Products (Class 6.2)

Shipping diagnostic specimens (UN 3373) or infectious substances (UN 2814) requires compliance with strict instructions like P650. If these products are also temperature-sensitive, complexity increases and using homologated isothermal packaging becomes essential.

Explore our range of packaging for biological and homologated isothermal productsFor Chemical Liquids and Solids (Classes 3, 6.1, 8...)

For transport of bottles, jerrycans or boxes containing chemical products (flammable, toxic, corrosive), the most flexible solution is often combination packaging like 4GV cardboard, which adapts to different types of inner receptacles.

Our 4GV cardboard boxes Our folding cratesFor High-Value Equipment and Prototypes

When the transported item is both dangerous, irreplaceable, and non-standard in shape (a prototype, military or aerospace equipment), maximum protection is required. The custom homologated flight case is the only solution that guarantees both compliance and absolute shock protection.

Contact our design office for a custom flight case solutionFAQ: Your Questions About Dangerous Goods Packaging

A Simple Method for a Strategic Decision

Choosing the right packaging for a dangerous good doesn't have to be complicated. By following this simple method, you can transform an intimidating task into a controlled process:

- Identify your product precisely using its Safety Data Sheet (UN Number, Packing Group).

- Select the packaging family whose characteristics meet your specific logistical needs.

Choosing compliant packaging is not just a simple transaction. It's a strategic decision that protects your company, your employees, your customers and the environment.

Every dangerous good is unique. If you have any doubt or specific need, take no risks.

Contact our experts for a diagnosis and find the packaging solution that guarantees your peace of mind.